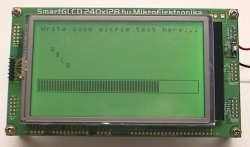

It draws some graphics boxes at XY pixel coords (240x128 grid).

The variable called barlength shows how easy it is to make a useful

screen object, in this case it is a display bargraph where the length of

the bar inside is controlled by the variable.

Download SG02_Simple_LCD.zip

Tut03 - Using the TouchPanel

This program introduces some very simple fast functions I created to

read the touchpanel XY coords of where it was touched.

Although MikroC PRO already has inbuilt touchpanel functions, MikroC does not.

Also, I wanted some functions that were very fast so they could read the

touchpanel during time critical PIC applications. Reducing the touchpanel

functions to the simplest and fastest code also makes them very easy to

understand.

These functions only read either X or Y from the touchpanel at a time,

so to get an XY coord you need to test both. However for some fast applications

where the PIC may be very busy and all you need is a "STOP" button on the

GLCD, you may only need to test X or Y, not both. Also to speed things up

you can test X or Y at separate times with your important PIC code running

in the middle.

This program tests the touchpanel X and Y continuously, and displays X and

Y on the screen. The X and Y values range from 0-255 and are simple ADC

values from the resistive touchpanel, they have not been calibrated to

become exact pixel coordinates.

Download SG03_Touch.zip

Tut04 - Using the TouchPanel in an interrupt

This program also uses my stripped-down TPfast() functions, but this time

the touchpanel is handled completely automatically in a timer interrupt.

The TPfast() touchpanel functions have been moved into their own file called

TPfast.C, this is explained in the source code.

The timer interrupt executes very quickly so it does not steal very much time

from your other processes, and it sequentially reads the X and Y from the

touchpanel each time the interrupt occurs. Also, if the touchpanel is not

touched it sets both X and Y to zero, as a very easy indicator your code

can use to know if the panel is touched.

The display shows the X Y coords (if the touchpanel is touched) otherwise

they are shown as 0 0. There is also a tiny graphic indicator box that

goes black if the touchpanel is touched.

The XY coords are still simple ADC coords 0-255 from the resistive

touchpanel hardware.

Note! There is a simple variable called tp_xy_locked that will

lock the XY values at their current state so the interrupt cannot change them.

This allows you to work with those values as long as you wish; process them,

display them etc and they will not change. Then just unlock the values and

the interrupt will update them with the latest touchpanel coords automatically.

Download SG04_Touch_Int.zip

Tut05 - Making an interactive bargraph control

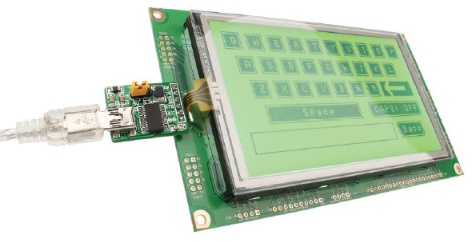

This program gets the touchpanel and GLCD working together to make a very

simple interactive screen object or "virtual control".

The control is a bargraph or bar slider. It can be touched with a

stylus or finger and sets the bargraph to the length where it was touched.

This is one of the most useful screen controls for adjusting parameters.

This project introduces a new function TP_convert_XY that converts the

touchpanel XY ADC values to actual screen pixel XY coords. This is useful

because it tells the exact place where the user touched the screen, and

then it is easy to determine where the user touched the control (the bargraph)

because both are specified in screen pixel XY coords.

Then the bargraph is set to the new position as touched by the user.

The screen shows the simple ADC XY coords directly from the resistive touchpanel

hardware (shown as TX and TY) and also shows the screen pixel XY coords

that were produced from calculation (shown as SX and SY). It also shows the

bargraph of course.

The source code is a bit crude (for simplicity) but the bargraph is defined

with its position and size that can easily be changed and the code should

easily be adaptable to bargraphs of different sizes.

Download SG05_Bargraph.zip

Tut06 - A 3-bargraph RGB LED PWM controller

This program uses 3 interactive bargraph virtual controls to set the

PWM (brightness) of each of the backlight RGB LEDs. This will let you

set the screen to any colour you like, including dimming the backlight for

power savings. Each RGB LED can be set to a brightness in the range 0-255

giving true 24-bit colour control (16 milion colours).

The LED PWM is done in a timer interrupt and is fast and simple,

and being timer locked it makes a stable and accurate PWM at about

280 Hz.

As a useful application it could be used as a RGB room light controller

for an entertainment room using the new high power RGB light fittings.

In this case the RGB backlight LED connections are already brought out to

connector CN9 on the SmartGLCD board, so you could connect that to your RGB

lighting driver, assuming it accepts logic level PWM signals.

As a lighting controller the SmartGLCD will also dim its own display to match

the room lights brightness and colour, a nice feature in a dark entertainment

room.

The display screen shows the 3 bargraphs for RED GREEN and BLUE, and also

the actual PWM value used (0-255 range). There is a simple "memorise"

and "playback" that demonstrates how easy it is to remember a user

setting for the lighting. Obviously the display layout could be made more

tidy and some more features added if this was to be used as a lighting

controller but all the basic features are implemented so it should not be

too hard to adapt to your needs.

Download SG06_LED_PWM.zip

SmartGLCD tips and tricks!

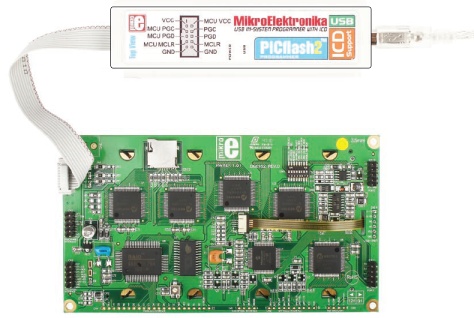

Adding a reset button!

This only took me about 2 minutes and I am so glad that it is there now!

A reset button is extremely handy for testing code while doing development.

Although a finished project might not really need a reset button I really

recommend you do this mod on your development SmartGLCD.

All that is required is a small pushbutton and a 220 ohm resistor.

The pushbutton and series resistor go between pin 7 of the ICSP connector

CN1 and ground (pins 9 and 10). See the photo above for how I wired it.

Note! Pin 7 of the connector is labelled "Vcc" which should have been

labeled "MCLR" or "Vpp". Either way it is connected to the MCLR reset

pin of the PIC. Using a 220 ohm series resistor means that it cannot

hurt any programmer that may also be connected to the SmartGLCD and

it is safe to press the reset button at any time.

Adding some PCB standoffs (legs)

I screwed four PCB standoffs onto my SmartGLCD to lift it up.

Now it no longer rocks around on the connectors etc when I press the

touchpanel. I used 25mm standoffs but 20mm are probably the best size.

Anything less than 20mm may not let you use the PICflash2 programmer

as it has an 18mm tall plug!

Software tricks - Keeping the original HEX code

I read the original demo HEX code that was in the SmartGLCD and put it

here.

The bootloader HEX file is also

available from MikroE, the bootloader (alone) is

here.

It can be very handy, for example when I had a GLCD initiaise bug

my SmartGLCD seemed to stop working, but programming the original HEX

code back into the SmartGLCD brought it back to life and proved the hardware

was fine. Warning! You can't program this HEX code using the bootloader as

it contains a bootloader, you can only program it with an ICSP programmer.

If you are using a bootloader and need a test HEX code to check your

SmartGLCD please use any HEX file from any of my tutorial projects above.

Initialising the GLCD right!

The GLCD has its own controller chip which is also a microcontroller.

If it intiialises wrong you can get some weird symptoms! The MikroC function

always initialises the GLCD properly, however if there is any delay between

powering up the SmartGLCD module where its pins are left floating before

calling the initialise function the GLCD can fail to initialise.

This delay can include boot up code etc.

Fortunately this is easy enough to fix, just make sure the following lines

are in your source code as one of the first things the PIC does. It holds all

the PORTJ pins low which keeps the GLCD controller IC in reset and with its

control pins in a defined state while the PIC does any boot up code including

delays. Then the GLCD should always initialise properly.

Note! The T6963C GLCD datasheet says the display should not be held in reset

for long periods as it may put DC on the display crystal and cause it to

deteriorate. It's wise to run T6963C_Init() fairly quickly after doing

the following code;

LATJ = 0b00000000; // Keep GLCD in reset

TRISJ = 0b00000000; // GLCD control port

Advanced Tutorials!

The following tutorials assume you have got up to speed now with your

SmartGLCD and you are confident enough to try some difficult projects...

Please don't contact me for tech support with these projects, generally

they were tested before being put up here but there may be some issues

with using these, so you are welcome to use my code but you might need

to think a bit. :)

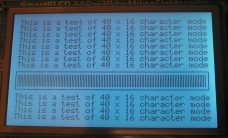

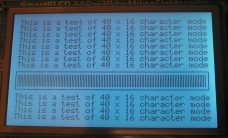

Tut07 - Using 40x16 text mode!

Well this one is not that difficult, but it is extremely useful!

Normally the GLCD is run with text mode "wide" font of 8x8 pixels and a text

display size of 30x16 characters to fill the screen.

This project

puts the GLCD in "narrow" text mode of 6x8 pixels, so the GLCD now displays

40x16 characters which is a massive improvement in display power, and because

the characters are identical it now looks much better as the characters now

have correct spacing as you would see on a 16x2 typical text LCD.

This project was very easy as the MikroC graphics functions seem to work

seamlessly with the new GLCD narrow font mode, so that's a credit to the

MikroC compiler. However even though the line and rect functions work ok

there will probably be issues with drawing images or icon images to the GLCD

because the graphic RAM addressing is now in bytes of 6 pixels wide (not 8).

So this is now in the advanced tutorials, it all seems to work great but you

might need to mess around a bit if you need to draw images to the screen.

The GLCD is initialised in 40x16 text mode, then it shows text lines of

40 chars wide which worked ok with the MikroC function. Also, a simple

graphics object was drawn across the screen to check that addressing and

graphics were still working ok.

To initialise in 40x16 narrow font mode you need to set the FS bit (bit6 on

PORTJ) and then set the graphics addressing width to 6 in T6963C_Init().

See the code, it's pretty easy.

This project also uses my simple RGB LED PWM system in the timer0 interrupt,

to set the RGB backlight LED to any colour.

Note! I will probably be using 40x16 text node from now on in my future

tutorials as it is a big improvement in the ability of the display!

Download SG07_40x16.zip

Tut08 - Making it draw FAST!

Note! Firstly I want to say that the MikroC compiler functions for

the T6963C GLCD are very nice, and do their job well!

But because they are designed to cover all

sorts of setups and situations they are not optimised for speed. Instead

they are optimised for plug-n-play, ie; they will work on many different

development platforms and different PICs etc.

This project is my first crude attempt to make the GLCD work FAST.

The goal was to strip everything to the bone and see what it can do.

I noticed on my previous tutorials and the MikroE SmartGLCD demo that it drew

text fast to the GLCD but seemed a bit slow to draw some graphic objects,

mainly filled boxes.

After examination of the MikroC functions, it seemed that every

graphic drawing function uses the Line() function, and the Line function

draws only one pixel at a time, and because it is capable of drawing

diagonal lines, every single pixel draw requires a 16bit multiply and

16bit divide! This is necessary for diagonal lines but is terribly slow for

drawing horizontal and vertical lines which are the most common and are

also used to draw all the screen objects like rectangles and filled boxes.

Basically, to draw a filled box the MikroC functions draw the entire

filled box with single pixels and every pixel uses lengthy math code!

Making optimised systems to draw horizontal and vertical lines.

This should not be too hard. The GLCD has graphic RAM in horizontal rows,

so it should be possible to write "black" bytes in sequence to make a fast

horizontal black line. The start and end of the line might need a bit of fuss

but the bulk of the line can be drawn VERY fast. Vertical lines will be many

times slower as they must be drawn one pixel at a time.

Optimising the commands directly to the GLCD

After reading the GLCD T6963C datasheet, it looks like every command to the GLCD

takes either 1, 2 or 3 bytes. The MikroC functions for sending these commands

are designed to allow multiple development hardware and different PICs and PIC

pins etc. This meant a lot of overhead, and after removing this overhead and

making new command functions that were ONLY for the SmartGLCD hardware and it's

PIC pins, I was able to speed these commands up twice as fast.

I used Timer1 set to exact uS to time how long it took to draw the

objects to screen, and displayed the time on screen.

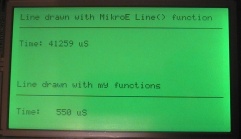

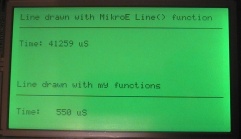

Horizontal line test results.

The first test result was pretty impressive! The MikroC Line function takes

41199 uS to draw a line of 240 pixels right across the screen. My test of drawing

bytes filled with 6 "black" pixels directly to graphics RAM took only 548 uS,

which was about 75 times faster! However I do want to state that my test was a

best possible case with no coordinate processing (I told it the exact graphic

RAM loacation to start) and with the line being fully byte-aligned so there

was no messing with pixel alignment at the start or end of the line.

A proper horizontal line function would have some coordinate processing and some

bit processing at the start and end of the line, so it would be quite a bit

slower, maybe 3 to 5 times slower.

But it does show that it is possible to draw objects very fast to the screen and

raises possibilities of making optimised functions to draw rectangles and

especially filled boxes that can be drawn from black horizontal lines.

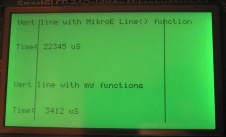

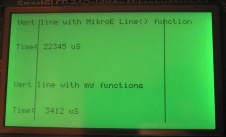

Vertical line test results.

The MikroC vertical line function ran at

a similar speed per pixel and took 22345 uS to draw a vertical line of 128 pixels.

My manual system had to re-address every byte, then draw a single pixel, and

it took 3410 uS to draw 128 vertical pixels. That was about 6.5 times faster

than the MikroC Line function.

At this point it looks like these fast graphic functions might be worth

refining into functions that are easier to use and still be quite a bit faster

on the SmartGLCD than the standard compiler graphics functions. A power-user

who needs very fast GLCD speed could even work with these functions as they are

and manually access the graphics RAM. These functions should also be excellent

for drawing graphics images, icons etc to the screen especially if they are

byte-aligned.

But for most SmartGLCD users the standard graphics functions in the MikroC

compiler are very easy to use and will allow fast practical code development!

And of course if using the development software MikroElektronika Visual GLCD

for Windows it generates all the GLCD buttons etc as source code so you would

be working with the standard compiler graphics functions there too.

That's why these fast graphics functions remain in the advanced section

of my tutorials page... They CAN be very fast if you go to the hassle of

making them do what you want. Use them at you own risk! ;)

Download SG08_Fast_GLCD.zip

Tut09 - Custom text characters

The MikroC compiler and examples didn't seem to have any support for making

custom text characters, so I had a go at it. :)

Reading the

Toshiba T6963C GLCD datasheet

was painful but paid off with

some information. To use custom text characters you tell it a RAM block

to be used (RAM blcoks are 2048 bytes) then the custom characters can be

stored in the last half of that RAM block (last 1024 bytes) as 128 custom

text characters which are each made by 8 bytes of horizontal pixels.

In this case the characters 0-127 are the standard text characters

(called internal CG) and the characters 128-255 are your custom text

characters.

Note! The MikroC functions to write text to the screen use an offset

of -32 which is necessary to make an ascii character like SPACE convert

to the correct CG address of 0. Because the MikroC functions do a -32

offset you can use the standard ascii characters which are 32-159, and

your new custom characters are offsetted -32 so they are now

160-255 range followed by 0-31.

This is a little annoying but it is covered in my source

code and it works fine, you still get all 128 custom text characters and

(of course) the standard 128 internal ascii characters.

The T6963C also has a "external GC mode" which is supposed to allow you

to use a full 256 custom characters instead of the internal CG characters.

Unfortunately I could not get this to work in my first attempts, I think

it might be because I am using the MikroC functions to communicate with

the GLCD and these functions may be forcing the GLCD to the standard

"internal CG mode".

Anyway my source code here gives you 128 working custom text chars.

The screen above shows the 4 custom characters that were made

and then displayed to GLCD using the standard text functions.

After the annoying Toshiba T6963C datasheet deciphering it worked out being

quite simple and easy to make the custom characters, and it is

super-easy to display them as you just use the standard MikroC

T6963C_Write_Text() and T6963C_Write_Char() functions.

Note!! One thing I did notice with the CG RAM is that it is

very retentive! Even with all power plugs removed from the SmartGLCD

for a full 3 minutes, when power was re-applied the RAM had its

memory perfectly intact. This is because the GLCD RAM chip goes into micropower

mode when shut down, and lives off one of the capacitors on the SmartGLCD

board. This might be good or bad, but just remember if you want the CG RAM to

be reset (or to change at all!) then you need to actually write to it.

Download SG09_Adv_Text.zip

Tut10 - Massive static RAM for free!

Wow! This one of those finds that makes your eyes pop. I was reading up on the

T6963C GLCD driver IC, and the other ICs on board the SmartGLCD. I found there

is a LY62256 (32 kbyte) static RAM IC that is used by the T6963C GLCD controller.

As the T6963C controller is capable of addressing 64k of RAM, it has been fully

connected (I checked the tracks) so the T6963C has access to 32 kbytes of RAM!

Above shows the LY62256 32kbyte static RAM chip on the bottom of the SmartGLCD.

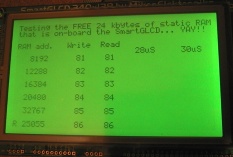

The RAM usage by the GLCD (with 40x16 text mode and 240x128 graphics mode) looks like this;

0 - 5119 (5120 bytes; graphics RAM, 40 bytes across, 128 bytes down)

5120 - 5759 (640 bytes; text RAM, 40 chars across, 16 lines down)

5760 - 6143 (384 bytes; spare?)

6144 - 8191 (2048 bytes; normally spare, but I use for 128 custom text chars CG RAM)

8192 - 32767 (24576 bytes; totally free for your enjoyment)

This is amazing! There is 24k (maybe 26+k) of totally free, nice fast static

RAM at your fingertips. For years I have been hinting that MikroE should

put a nice big static RAM on their BigPIC development boards and now they

finally did it and didn't tell me... ;)

Accessing the static RAM.

The MikroC functions do not include any functions for READING from the

T6963C GLCD controller or from its static RAM. As I had already written my own

very fast functions to write data and commands to the GLCD it was easy to write

one more function that reads a data byte from the GLCD (which it gets from its

static RAM chip).

Writing to the static RAM;

1. Send the 16bit address to the GLCD, and a "set address" command

2. Send the data byte to the GLCD, and a "write byte" command

Reading from the static RAM;

1. Send the 16bit address to the GLCD, and a "set address" command

2. Send a "read byte"command, then read the byte from the data port

There are some shortcuts, like writing and reading sequential bytes can be

used with the same auto-increment shortcuts as used for writing to graphics

RAM to display things. There is also a block mode, as used for writing graphics,

it can be used for fast writing and reading to the static RAM.

My functions are optimised for the SmartGLCD hardware for speed, so even

including the overhead of sending the 16bit address it only takes about 28uS to write

a byte to RAM and about 30uS to read a byte from RAM. If you are doing sequential

writes or reads to RAM (using auto increment address) it is about 2.5 times faster

than that (around 12uS per byte), and block writes and reads can be about

5 times faster (about 7uS per byte).

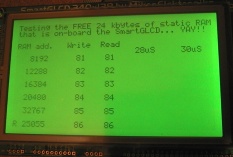

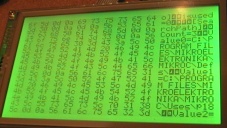

The screen above shows 5 RAM addresses from 8192 to 32767 all being constantly written

to and read back, if there is any failure there is an "ERROR!" text tag that will

appear. The bottom line shows a "random" address that is also tested the same way,

the random RAM address is changed every time but is always between 8192 and 32767

(it is always in the top 24k of RAM).

The 2 time fields show in actual uS the amount of time to set address and write a byte

and to set address and read a byte.

Please don't be afraid to use this RAM! This is a very powerful resource on

your SmartGLCD and it is easy and reliable to use. It is just as easy as

writing to the GLCD graphics ram, except of course nothing is shown on the

screen. ;)

Note! Just be aware if anything writes text or graphics to the GLCD the

RAM address will have been changed (of course), so you need to set the address

again to read or write a byte in the RAM.

Note 2! One thing I did notice with the static RAM is that it is

very retentive! Even with all power plugs removed from the SmartGLCD

for a full 3 minutes, when power was re-applied the RAM had its

memory perfectly intact. This might be good or bad, but just remember

if you want the static RAM to change then you need to actually write to it.

Download SG10_Free_RAM.zip

Tut11 - Big Digits

Having lots of text (ie 40x16 chars) on screen is great, but I also wanted

the ability to display larger digits that can be seen from a distance, which

will make the SmartGLCD good for instrument applications, like a frequency meter or

as a wall mounted display.

The T6963C GLCD driver only has one inbuilt font, the standard 6x8 font

(same font can also be displayed as 8x8 with extra blank pixels). I considered

using graphics sprites as large characters, but soon realised that it would be

better to use custom text characters as they draw to the screen 8 times faster.

It also means the large font characters are stored in the GLCD RAM and

the GLCD controller does all the work of displaying them, a nice type of

simplicity. This turned out to work very well, because I had already found

out in Tutorial 09 that custom text characters were easy to do. It also allows

text overlay as XOR etc, same as the normal sized text characters.

Above is the bitmap I made and used to generate the big font data table, the digits

are standard style LCD type 5x7 digits but doubled in size so they are actual

10x14 pixels then one pixel space added all around to make 12x16. Once the

digits were 12x16 they were easily separated into 4 custom text characters

of 6x8 pixels each (as a 2x2 character block).

Because there are 128 custom text chars the max digits you can make this way is

128/4 or 32 digits. I settled for the numerals 0-9 and some other characters to

display volts, amps, watts, temperature C and F etc. That should be enough to

make some useful displays. It's a total of 19 characters.

Using the big digits is very easy, you can use them the same way as the MikroC

functions to draw a character or character string to the screen. And they are very

fast so you can do a display that is rapidly changing and it still looks very clean

drawing to the screen.

Just #include the file "SGBigNumbers.c" and you can use the large numbers in your

own projects with the functions I have provided.

The screen above shows the normal sized digits at the top, then the new double-sized

big digits. Then a couple of sample displays. You can see from the C source code

it is extremely easy to use the big digits. There is a 5 digit counter at the

bottom drawing all 5 digits 20 times a second. At the bottom left there is a

digit 0 drawn over another digit 0 so you can see how they are drawn from 4 text

characters.

Download SG11_Big_Text.zip

Tut12 - Serial receive terminal

This is a serial terminal, for receiving and displaying serial (RS232 etc) data,

and can be used as a piece of test equipment.

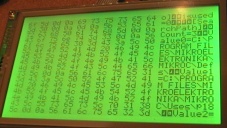

It can be set for most common baudrates and will receive and store up to 2560

serial bytes. Then the bytes can be displayed on the "terminal" screen as

ascii characters or as hex/ascii combination (see screenshots below).

This is a fairly large project that calls on some of the earlier tutorials.

It uses custom text characters to display some of the non-ascii codes like line

feeds etc. It uses an interrupt to receive the serial bytes in real time up

to 115200 baud, and automatically display them later as the screen is drawn.

The setup screen is shown above. Here you select the baudrate, and which screen

of 640 ascii data characters you want to view (as the total recording storage

of 2560 bytes is 4 screens of 640 bytes each). At the bottom of the screen are

buttons to clear the data storage memory and to switch back to the terminal screen.

It could be made more pretty but this gives enough functionality for me to use this

as a piece of test equipment. The screen also shows the 7 custom text characters

and the touchpanel X Y coords, these are turned on for development but can be

turned off easily in the code (see the comments).

The screen above shows some serial data (sent from a text file) and it is shown

as ascii characters. You can see the carriage return/line feed pair of bytes shown

as custom text characters and some NULL (zero) characters added at the end

of the file, caused by me unplugging the USBserial adapter.

This screenshot gives you an idea of the amount of data that can be shown

on the SmartGLCD in 40x16 text mode.

Above shows the same data but displayed as hex/ascii. I copied the format

of many old Dos editors etc that show the hex data on the left and the same

data as ascii in the right column. It displays 10 characters per line, so

in this mode you can only display 160 characters on a screen. You could

easily add some scrolling features etc, just by making some additions to

the source code. This hex/ascii mode is quite useful for examining received

serial data.

This is a large project and the source code is a little untidy. But it works

well and is a powerful tool for displaying serial data, even with large streams

like a GPS NEMA output which is usually a few hundred bytes in total, remember

this project will store and display a massive 2560 received bytes!

Note! A useful feature to add would be an auto start/stop mode, so that after a memory

clear it will not start recording serial bytes until there has been a pause in

sending, then it will automatically stop on the next pause, so that all bytes

between the 2 puases are recorded. I have used this system before for recording

repeated data like GPS NEMA streams. However I have not included auto start/stop

in this project as you can add it easily enough if you wish.

Note 2! The MikroC Usart functions are very easy to use, and are used in this project.

However for the 8MHz xtal they only allow baudrates from 2400 to 115200. If you manually

configure the PIC usart baudrate generator settings you can get much lower baudrates.

Download SG12_Serial_Term.zip

Tut13 - Sinewave DTMF generator

New - 21st Feb 2011

This uses a DDS algorithm to generate 2 simultaneous sinewaves of

precise frequencies for DTMF telephone tone generation. Although my code

can make good precise sinewaves even on a small PIC 12F or 16F I had the

SmartGLCD handy so I did it on that. :)

If you want to see how the algorithm allows multiple simultaneous

sinewaves of precise frequencies to to generated please check out my

zero-error timing algorithms page.

One sinewave table is used to generate all sinewave frequencies. This table

must be a binary size, I used a size of 64 tables entries (see source code).

The algorithm loads the sine table into the PIC PWM module (CCPR2) with

a mathematically exact timing so it can generate any sinewave frequency with

high precision. In this project it generates 2 simultaneous sinewaves of

different frequencies to make any of the 16 DTMF "tones".

The 2 generated sinewaves are added together, and loaded into a single PWM

module so the one PIC output pin generates the DTMF waveform.

The PWM module runs at 62 kHz, so it is easily filtered with a resistor and

capacitor to make the Dual Tone Multi Frequency waveform required by

telephone systems.

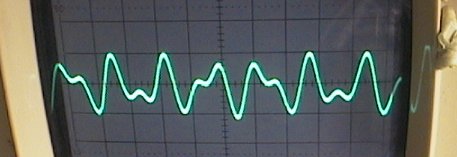

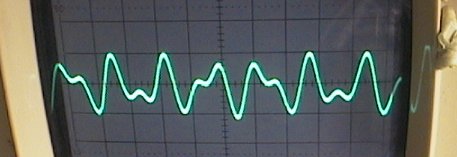

Above you can see the flawless looking 697 Hz sinewave, which tested as 697.00 Hz

on my frequency meter. This was generated with a single BDA 24bit process.

On the right you can see the DTMF output of 2 independent sinewaves 697 Hz and

1209 Hz, both generated by 2 BDA processes and 1 PIC PWM output pin.

This looks textbook perfect, I'm very pleased with the quality of this dual

independent precise sinewave DTMF tone that only required one PIC PWM pin.

(Note; I have tweaked the horiz scale on the 'scope for better viewing).

(code below is an updated example; 6 Mar 2011, it is "twist compenstaed" to

better match telephone system specs.

// 24bit DDS algorithm for dual simultaneous sinewaves on one PWM module

// this is an example for DTMF generation

// 8 MHz xtal (8 MIPS on PIC 18F PLL)

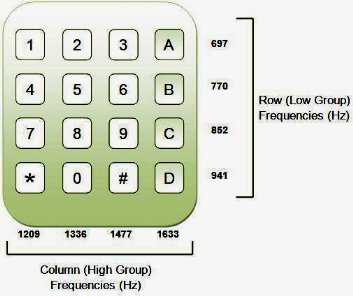

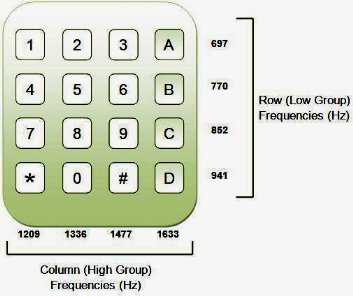

#define Frow0 46775 // 697 Hz DTMF rows

#define Frow1 51674 // 770 Hz

#define Frow2 57177 // 852 Hz

#define Frow3 63149 // 941 Hz

#define Fcol0 81135 // 1209 Hz DTMF columns

#define Fcol1 89657 // 1336 Hz

#define Fcol2 99120 // 1477 Hz

#define Fcol3 109589 // 1633 Hz

unsigned long waveA absolute 0x15; // 32bit accumulator for the sinewaves

unsigned char waveA_2 absolute 0x17; // overload for fast access to byte 2

unsigned long waveB absolute 0x19;

unsigned char waveB_2 absolute 0x1B;

unsigned char pwm;

// This uses dual sinewaves of 28% different amplitudes, to match the spec for "twist" in

// telephone DTMF to ensure the higher freq has a higher amplitude, to cope with line losses.

const unsigned char sine64low[64] = {

39,42,46,50,53,57,60,63,66,68,71,72,74,75,76,77,77,77,76,75,74,72,71,68,66,63,60,57,53,50,46,42

39,35,31,27,24,20,17,14,11,9,6,5,3,2,1,0,0,0,1,2,3,5,6,9,11,14,17,20,24,27,31,35};

const unsigned char sine64high[64] = {

50,54,59,64,68,73,77,81,85,88,91,93,95,97,98,99,99,99,98,97,95,93,91,88,85,81,77,73,68,64,59,54,

50,45,40,35,31,26,22,18,14,11,8,6,4,2,1,0,0,0,1,2,4,6,8,11,14,18,22,26,31,35,40,45};

// loop and generate dual sinewave DTMF tone

PR2 = (128-1); // PWM at period = 128

while(1)

{

while(!PIR1.TMR2IF); // sync to start of PWM cycle

PIR1.TMR2IF = 0;

// calc the A sinewave,

waveA += Frow0; // zero error Accumulation

pwm = sine64low[waveA_2 & 0x3F]; // Binary Divide output (/65536) and keep 6 bits

// calc the B sinewave, and ADD the 2 waves together

waveB += Fcol0;

pwm += sine64high[waveB_2 & 0x3F];

pwm = (pwm >> 1); // scale 0-200 back to 0-100 for PWM

CCPR2L = pwm; // load added sinewaves into PWM module

}

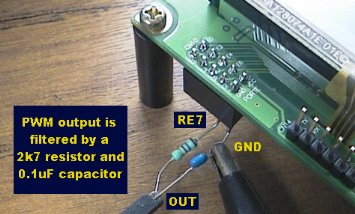

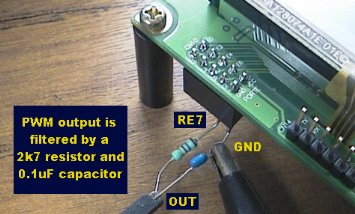

Above shows all the hardware that is required, a single PIC PWM output pin (PORTE.F7) a

2k7 resistor, and a 0.1uF cap.

This keypad above shows the way the 2 frequencies are used to represent telephone data.

The right column (col = 1633 Hz) is thought not to be used in telephone

exchange systems.

An important modification I made to my SMartGLCD was to replace the

8 Mhz ceramic resonator with a 8 MHz xtal. The resonator on the SmartGLCD

was ok for most jobs but measured 0.4% fast, and has now been replaced with

a crystal that was tested at less than 30 PPM (parts per million) error.

Now it can be used for reasonably precise frequency generation.

This was a very easy modification to make.

You just press the screen to select the DTMF frequencies. You can also

turn either freq off to check the other freq is a sinewave and check its

frequency is accurate. You may find a tiny percentage error on all the

frequencies, this is because your SmartGLCD has the ceramic resonator

installed, changing to a 8MHz xtal will fix this. Full source code and HEX file

etc provided below.

Download SG13_DTMF.zip

I plan to add more tutorials and SmartGLCD projects at a later date as time

allows.

- end -

[Back to Home Page]